|

BALL

JOINT

(ALL MODELS EXCEPT HOCKEY)

The BOLA delivery head is mounted on a large ball joint,

which allows almost infinite adjustment of line, length and angle

of delivery.

Slacken the large knob at the front of the machine to loosen the

ball joint clamp. This allows you to select the desired position

for the delivery head before retightening the clamp.

When using the machine you may find it useful to leave the ball

joint loosely clamped to allow some movement for fine line and length

adjustment.

VERNIER

LENGTH

ADJUSTMENTS

For fine line adjustment, turn the small black knob clockwise to

move the line of delivery to the left, and anti-clockwise to move

it to the right.

Please note: When the machine is set up for spin, the Vernier controls

will have different effects on line and height.

DELIVERY

VARIATION

You will notice that even with the ball joint firmly tightened there

is still some movement of the delivery head. This allows the operator

to simulate a match situation and vary the line and length of individual

deliveries.

To do this, use the handlebar to temporarily move the head and alter

line and length as required. When the handlebar is released, the

handlebar will return to its original position (as long as the ball

is firmly clamped).

VERY

IMPORTANT

It should be remembered that a cricket bowling machine is potentially

very dangerous if it is not operated responsibly. Under no circumstances

should children without the supervision of qualified adults use

the machine.

All batsmen, machine operators and attendants must wear protective

clothing (helmets with face guards, pads etc.) and be constantly

aware of BOLA and the batsman.

After any adjustment of line, length or speed, feed a ball through

the machine with no batsmen to ensure that the adjustments have

been made correctly.

|

|

BOLA

28 BALL

AUTOMATIC FEEDER

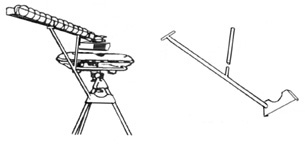

An automatic ball feeder to fit all BOLA machines. Fitted in less

than two minutes it feeds a ball into the machine every 7 or 11

seconds (as selected). Optional remote control on/off switch allows

interruption of the sequence when required. Warning lights indicate

the release of ball.

|

|

ASSEMBLY

Remove the automatic feed from its packaging. You should have two

parts:

1 Ball Rack and 1 ‘Y’ frame which attaches the feeder

to the machine.

To fit the feeder to the machine the ‘Y’ support frame

is slotted onto one of the legs so that it is on the same side of

the machine as the control panel.

Switch on the bowling machine and adjust it for the desired line,

length and speed.

Place the ball rack on the support frame so that it sits in the

open ‘U’ at the outermost end of the ‘Y’ and

the adjustable tube socket fits over the spigot part of the ‘Y’.

Slackening the black plastic knob will allow the feeder to be positioned

so that it drops balls cleanly into the machine. Tighten the black

knob when the required adjustments have been made. It may be necessary

to re-adjust this if the line or length of eth machine is adjusted.

Plug the 3-pin DIN plug into the socket on the left hand end of

the control panel.

BALL

FEEDER OPERATION

With the feeder switch in the ‘Off’ position, plug the

feeder into the socket on the left hand end of the bowling machine

control panel. The switch has five positions, which have the following

functions.

|